Safety Measures for

Lithium-ion Batteries

The recent advancements in lithium-ion battery technologies are rapidly progressing toward higher performance and increased capacity. And the application fields of lithium-ion batteries (LIB) are continuing to expand from mobile IoT devices and home appliances to battery energy storage systems, large scale backup power systems for data centers, electric vehicles, and future mobility.

The enhanced performance and expanded application areas of lithium-ion batteries make a significant impact on our community. However, there is a risk of heat generation or ignition from lithium-ion batteries, which is one of the drawbacks associated with them.

Dangers associated

with Lithium-ion Batteries

If lithium-ion batteries are subjected to improper charging conditions, short-circuits, vibration, mechanical shock, too high or too low temperature, or other excessive conditions during their use, storage, or transportation, they may experience the following issues:

- Leakage of various gases from LIB due to increased inner pressure

- Electrolyte leaks

- Pyrolysis reaction of electrolyte

- Thermal runaway*

* Thermal runaway is a positive feedback reaction that may occur within a battery when the temperature

inside has reached a certain temperature during charging or discharging, or in the event of other failures.

Once this process has begun, it can go out of control.

These problems are caused by a rapid rise in the temperature of the electrolyte within a lithium-ion battery, which can be triggered by elevated ambient temperature, high pressure, or other external factors. In the worst case, they may lead to an accident such as a fire or explosion.

Heat or smoke generation

Explosion and fire due to thermal runaway

Gases generated in abnormal conditions

of

lithium-ion batteries

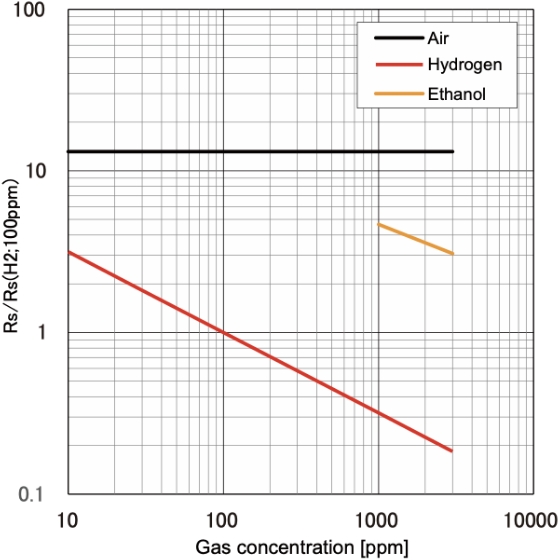

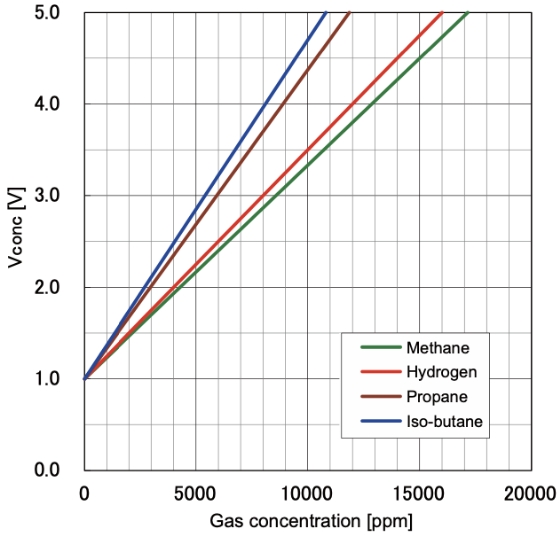

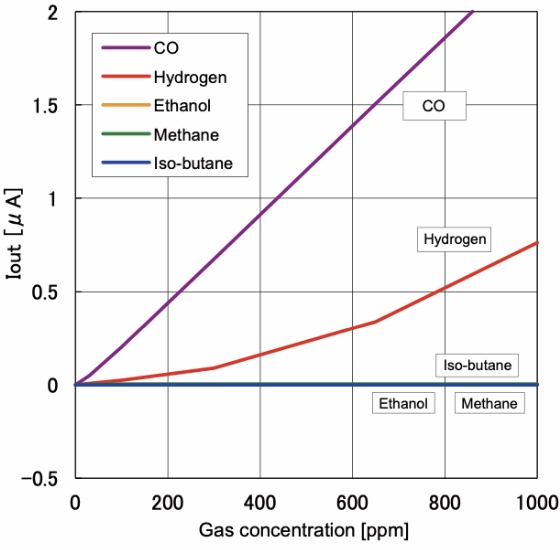

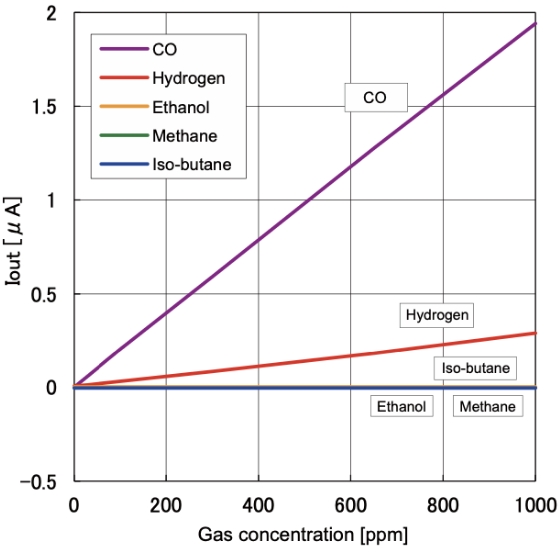

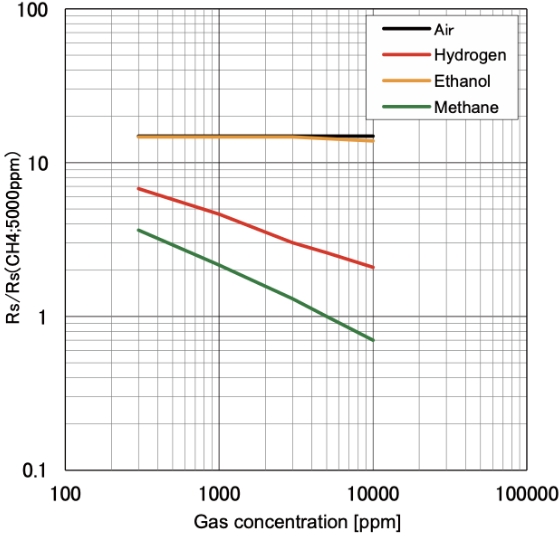

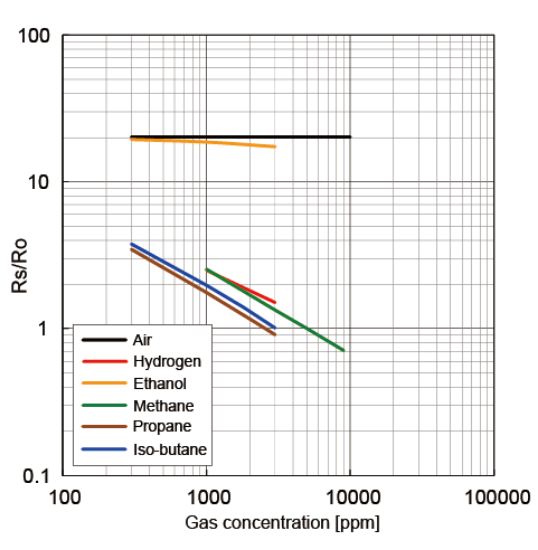

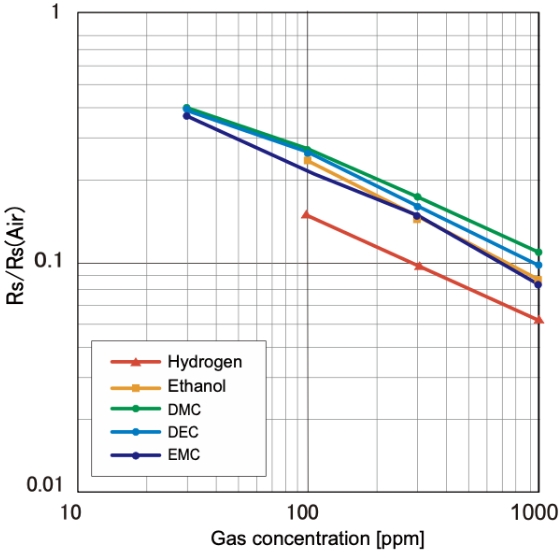

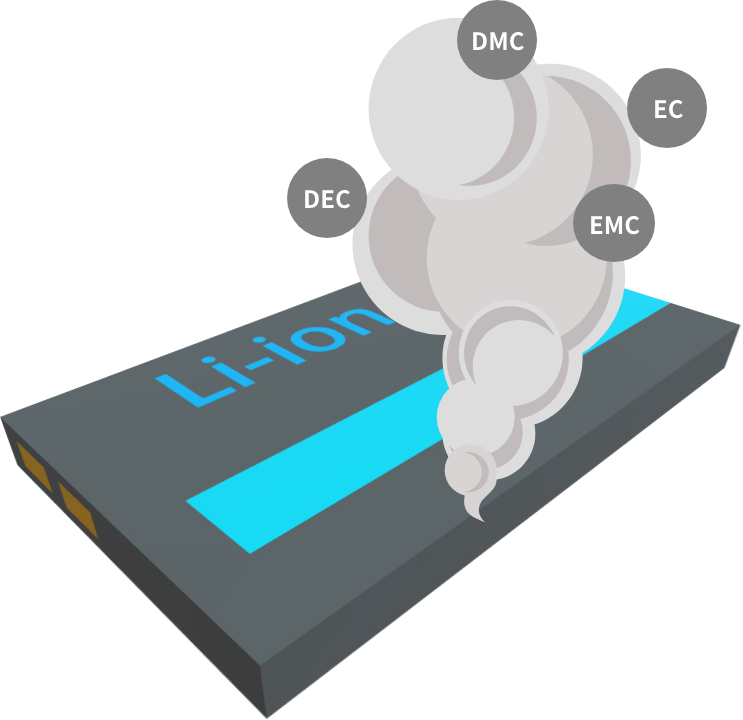

Typical gases that can be produced inside a LIB when certain abnormal situations occur with the LIB include hydrogen (H2), carbon monoxide (CO), methane (CH4), carbon dioxide (CO2), and hydrocarbons series volatile organic compounds (VOCs: EMC, DEC, DMC, EC, etc.). These hydrocarbons VOCs are thought to be vapors or pyrolysis products of the organic solvent used for the electrolyte inside a LIB.

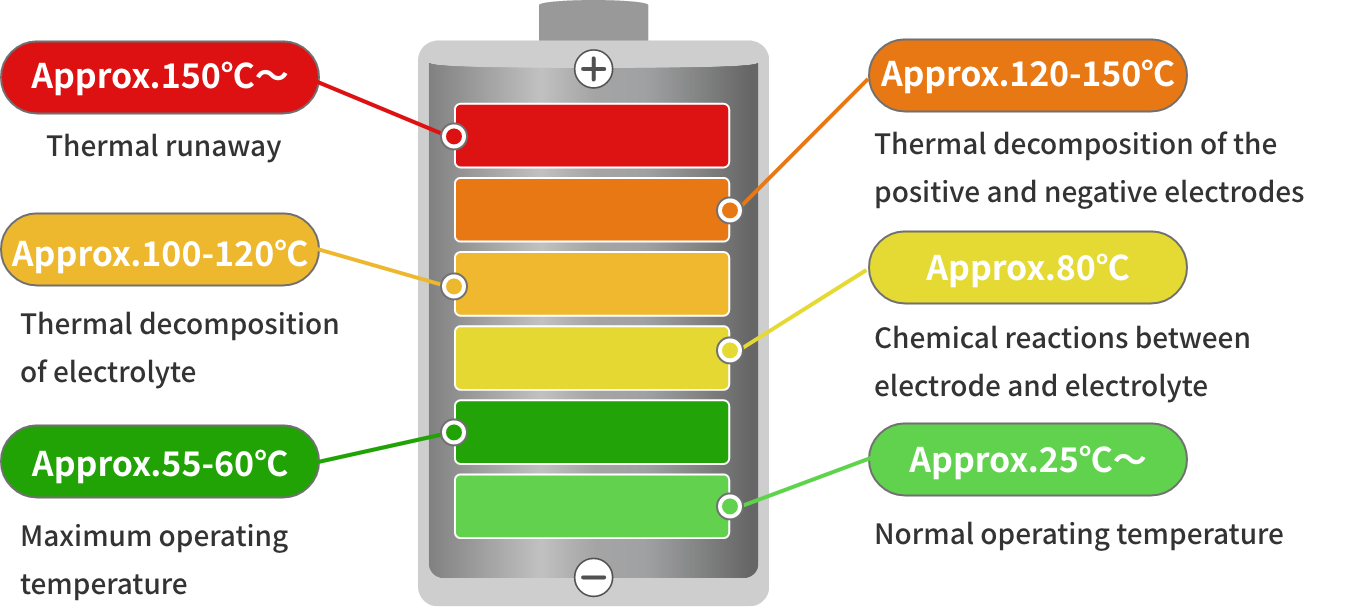

When a lithium-ion battery generates abnormal heat, thermal decomposition of its resin materials and electrolytes begins to occur. As the internal temperature rises, various kinds of gases are generated and leaking out.

Ambient temperature

~ Approx. 120℃

- EMC:(Ethyl Methyl Carbonate)

- DMC:(Dimethyl Carbonate)

- DEC:(Diethyl Carbonate)

- EC: (Ethyl Carbonate)

etc.

Approx. 120℃

- H2O: (Water)

- CO2:(Carbon Dioxide)

- HF:(Hydrogen Fluoride)

- H2: (Hydrogen)

- CO:(Carbon Monoxide)

etc.

Approx. 150℃ ~

- H2: (Hydrogen)

- CO: (Carbon Monoxide)

- CH4: (Methane)

- C2H4: (Ethylene)

- C2H5: (Ethyl Radical)

- CO2: (Carbon Dioxide)

etc.

Line-up of Gas Sensors for

Enhancing Lithium-ion Battery Safety

Figaro gas sensors have a proven track record, and are known for their high sensitivity, reliability, compact size, long life, and affordable price. The use and applications of Figaro gas sensors are already widespread in a variety of equipment using lithium-ion batteries.

Hydrogen (H2) Sensors

Carbon Monoxide (CO) Sensors

Methane (CH4) Sensor

Hydrocarbon gas (propane, butane, etc.) Sensors

VOC Gas Sensor

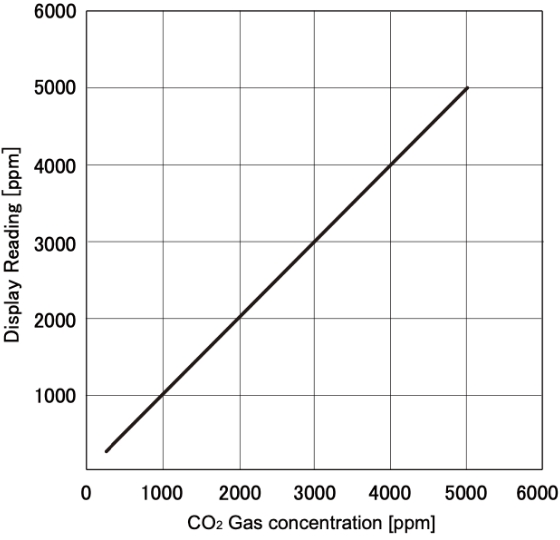

Corbon Dioxide (CO2) Sensor

Examples of LIB Applications where safety measures with gas sensors are desirable

Once an accident occurs due to lithium-ion battery failure in facilities or equipment where many large LIBs are used, serious damage can be expected.The incorporation of multiple types of gas sensors in equipment that uses LIBs has the potential to detect abnormal conditions in LIBs at an early stage and reduce damage caused by LIB failure.

-

Industrial and commercial ESS (Energy Storage Systems)

-

UPS (Large Backup Power Supply)

-

LIB manufacturing plants

-

Industrial equipment

-

Home and consumer use storage batteries

-

EV (Electric Vehicles)

-

Communication base stations /Data centers

-

Commercial and business facilities

Gas Sensor Application Examples that Contribute to Enhanced LIB Safety.

Figaro gas sensors, which are compact, long-lasting, highly sensitive, and highly reliable, have earned an exceptional reputation for their proven track record in safety applications.They are already used in various lithium-ion battery monitoring systems and other applications.

Case of Company NMultiple Environment Sensor System MES-92/93

-

1. Gas Detection Function

- Continuous monitoring, No need for sensor replacement for a long time

- Adoption of proprietary algorithm

-

2. External Notification Function (Contact Output)

- Compliant with IEC62933-5-2 and JIS C 4441

-

3. Compact Size

- 50(W) x 78(H) x 100(D) mm, less than 250g

- Mountable on DIN rails

-

4. Remote Communication Function

- RS-485 (Wired) / 920MHz Band Multi-Hop (Wireless)

For more details, please visit the manufacturer’s website.

https://nissin.jp/news/240425/

https://nissin.jp/product/kankyo_sensor/index.html